How to Use Data to Improve WooCommerce Inventory Forecasting

Running out of stock on a bestseller is a heartbreak moment for any store owner. It’s not just a lost sale—it’s a missed opportunity, a dent in your customer experience, and a dark spot on your projected revenue. On the flip side, having stacks of unsold inventory collecting dust and depreciation isn’t great either.

Welcome to the sticky balancing act known as WooCommerce inventory management. The good news? You don’t need to rely on wishful thinking or educated guesses anymore. You’ve got data, and when used right, it becomes your crystal ball for inventory forecasting.

In this guide, we’ll show you how to use your store’s existing WooCommerce performance data to improve your inventory forecasting—so you can better predict demand, prevent stockouts, and avoid costly overstocking. And yes, we’ll show you how Alpha Insights can help you make that process a whole lot smarter (and easier).

What is Inventory Forecasting and Why Does It Matter?

Inventory forecasting is the process of predicting how much stock you’ll need over a set period of time based on past sales data, seasonal trends, purchase patterns, and marketing campaigns.

Why does it matter? Because inventory ties up your cash. You either:

- Overstock: Lose profit margin due to storage costs, product obsolescence, or deep discounting just to move stock

- Understock: Miss out on revenue, pay rush shipping costs, or send customers elsewhere when you run out

Both scenarios chip away at your bottom line. But using accurate, up-to-date data, you can find the middle ground and optimize inventory with confidence.

The Problem with Traditional Inventory Forecasting

Many WooCommerce store owners are forecasting inventory with outdated spreadsheets, back-of-the-napkin math, or set-and-forget reorder points. That might work if you’re selling only a few SKUs with predictable patterns. But for growing stores with dynamic marketing, sales, and product variety—it’s a recipe for trouble.

The reality is this:

- Demand changes by season, channel, and campaign

- Not all customers buy the same quantities consistently

- Supply chains, lead times, and shipping costs can vary

- Your money is limited, and inventory should be optimized for profit

Enter… data-driven forecasting.

What Data You Actually Need to Forecast Inventory Accurately

Forecasting isn’t just about “looking at last year.” While historical sales play a big role, the best forecasts consider multiple data points that influence product movement.

Key data to factor into inventory forecasting:

- Historical sales volume: What are your average weekly/monthly sales per SKU over the last 6-12 months?

- Seasonal and trending behavior: Are there peaks during holidays, promotions, or seasonal peaks?

- Lead times: How long does it take to restock items from your supplier?

- Purchase frequency: How often do repeat customers buy?

- Product-level profitability: Which products are actually moving the needle (not just moving off the shelf)?

- Upcoming promotions: Will email campaigns, influencer drops, or sales events spike demand?

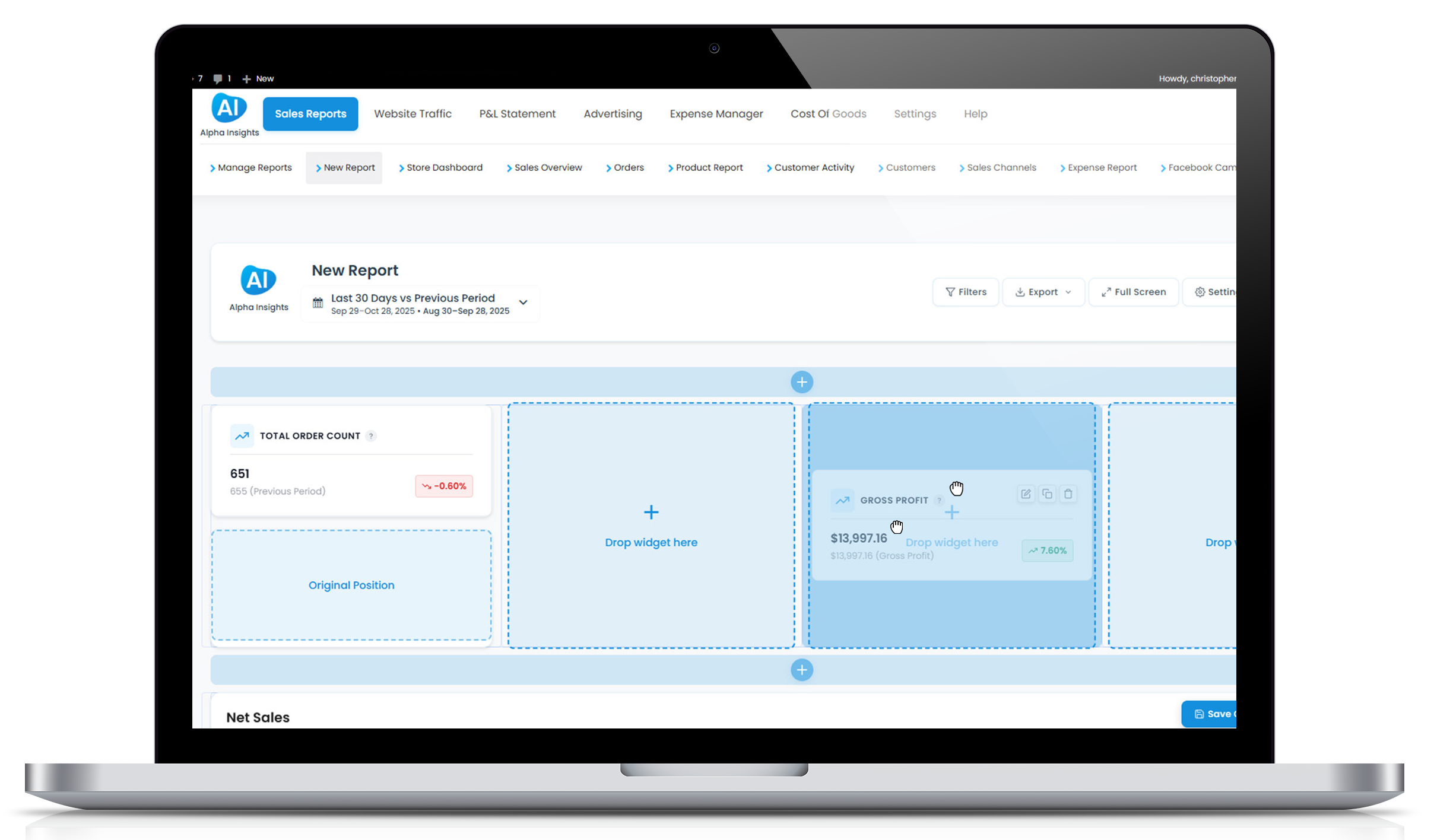

Alpha Insights brings many of these data points together into one clear picture—tracking product performance, profitable inventory movement trends, and forecastable revenue based on your real-time data.

Using Data to Create Smarter Inventory Forecasts

Now that you know which data matters, let’s break down how to actually use it to plan your inventory properly.

Step 1: Pull Historical Sales Data by SKU

This should be your starting point. Run a report that shows units sold of each SKU over the last 3, 6, and 12 months. Don’t just look at top-line sales—look deeper:

- Are sales increasing, decreasing, or plateauing?

- What visual patterns emerge across time periods (e.g., month-over-month)?

- Do days of the week or marketing campaigns influence sales velocity?

Inside Alpha Insights, you can not only view sales per SKU, but also layer in actual net profit per product, customer behavior, and marketing attribution so you’re not just forecasting on volume—you’re forecasting on value.

Step 2: Factor in Lead Times and Supplier Variability

Forecasting should help you avoid emergency reorders. Factor in how long it takes from placing a PO to having inventory ready to sell. This includes manufacturing time, shipping duration, customs (if international), and warehouse receiving.

For example: if your top product sells 100 units/month and your supplier takes 6 weeks to deliver, you’ll want to reorder when you hit at least 150 units in stock (and preferably earlier if you’re running ads or heading into a high season).

Step 3: Segment Inventory by Product Type

Not all SKUs should be forecasted equally. Some products are evergreen, others are seasonal. Some are bought in bulk, others as one-offs. Treat forecasting like financial planning: segment by behavior.

Segment your forecast by:

- High-volume SKUs: Often more consistent, but more dangerous if stockouts occur

- Seasonal items: Ramp up forecasting ahead of time (think: Black Friday, Summer, Christmas)

- Accessories or add-ons: These may follow the sales rate of your main products

- Low performers: Watch carefully—do they need a price bump or a clearance strategy?

With Alpha Insights, you can tag and group products, then analyze their performance not only by revenue, but by profit margin and customer retention impact.

Step 4: Incorporate Marketing Data into Forecasting

Campaigns drive spikes. If you’re about to run a sale, influencer drop, email promotion, or product relaunch, you need to prepare your inventory well in advance.

Marketing data to align with inventory:

- Expected traffic bumps (e.g., “our average campaign sees 2,000 visits/day”)

- Assumed conversion rate (e.g., 3% of visitors convert)

- Target product(s) for the campaign

- Sales velocity from similar past campaigns

Inventory forecasting without this context is like planning a trip without checking the weather. Alpha Insights lets you analyze which campaigns drove the most profitable inventory movement—so you can plan based on past performance, not hunches.

Step 5: Use a Rolling Forecast, Not Set-and-Forget

Your inventory plan should evolve. A rolling forecast means updating your predictions based on new information—sales trends, supplier delays, marketing changes, or new product additions.

How to keep a rolling forecast in motion:

- Set forecast reviews on a weekly or bi-weekly basis

- Update assumptions (growth, lead time, campaign impact) regularly

- Use visual dashboards to track inventory burn rates and reorder points

- Monitor cash flow to balance investment in inventory vs. marketing

The better your forecasting dashboard, the faster you can update and act. Alpha Insights supports this with real-time profit metrics combined with product-level analytics, so you can pivot ahead of problems instead of reacting late.

Special Considerations for WooCommerce Stores

Not all eCommerce platforms are created equal. WooCommerce users enjoy a huge degree of flexibility—but that also means many store owners are left stitching together fragmented data across WooCommerce, shipping tools, expense spreadsheets, and ad accounts.

This disjointed setup makes accurate forecasting hard unless you proactively pull data together.

Challenges WooCommerce store owners face:

- Hard-to-track product costs across suppliers

- Unlinked advertising spend vs. product performance

- No native WooCommerce inventory forecasting capabilities

- Difficulty monitoring net profit per product

If any of these sound familiar, Alpha Insights was built just for you. It connects the dots between your store, customer data, expense records, and ad performance—unlocking forecasting ability without the spreadsheet nightmare.

Turn Forecasting into a Growth Lever

Forecasting shouldn’t just be about avoiding problems. When done right, it becomes a strategic advantage:

- Run leaner: Keep less capital sitting in unsold inventory

- Act faster: Plan reorders in advance, reducing last-minute supplier chaos

- Boost profitability: Invest more in moving products that deliver high margin and scale

- Build trust: Keep items in stock when marketing says they are, winning customer loyalty

Think of forecasting not as risk avoidance—but as your tool for making smarter inventory bets that move your business forward.

How Alpha Insights Simplifies Inventory Forecasting

Alpha Insights gives WooCommerce store owners clear, actionable data for smarter decisions—including inventory planning. With unified reporting that brings together expense tracking, product sales, marketing insights, and profit analytics, you’ll finally see the full picture behind your inventory.

With Alpha Insights, you can:

- View product-level sales, revenue, costs, and profit margins

- Assess how ads and campaigns affect sales velocity per SKU

- Spot trends across time to prep for seasonal shifts

- Forecast profit—not just quantity—so your cash goes where it makes the most impact

Inventory forecasting isn’t just about what you’re selling—it’s about what you’re profiting. Install Alpha Insights and make the leap from reactive stock decisions to proactive inventory growth strategies.

Final Thoughts: Better Forecasts, Better Business

Inventory forecasting doesn’t need to be intimidating. With today’s access to WooCommerce data and tools like Alpha Insights, even small and mid-sized stores can take advantage of the kind of precision planning that used to be reserved for giant retail operations.

It all comes down to this: Less guessing. More knowing. A small shift in how you forecast can significantly increase your profitability, improve your customer experience, and reduce risk across your business.

Start there. And let your data do the rest.